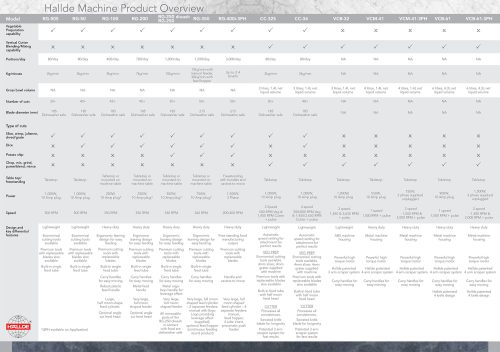

The VCB-61 & VCB-62-3PH are robust, reliable vertical cutters designed for quick preparation in professional kitchens. The machines chop, grind, mix, puree, blend and mince.

VCB-61

Single phase machine with single speed with pulse function. Includes stainless steel bowl with gross volume 6 litres and net liquid volume of 4.3 litres.

VCB-62-3PH

3 phase machine with two speed and pulse function. Includes stainless steel bowl with gross volume 6 litres and net liquid volume 4.3 litres.

Type of preparation

Chops, grinds, blends and mixes, purees, blends and minces..

Prepares aromatic butters, dressings, desserts, herb oils, thickenings, mayonnaise, sauces, soups, minced meat, purées, pâtés, etc.

Prepares meat, fish, fruit, vegetables, onions, parsley, nuts, almonds, parmesan, mushrooms, chocolate, etc.

Users

Restaurants, shop kitchens, diet kitchens, bakeries, retirement homes, schools, fast food outlets, catering, day care centres, salad bars, pizzerias, ships, central kitchens, institution kitchens, and more.

High capacity with smart lid

The six litre bowl has a tightly sealing lid and an extra high centre tube. This increases the net volume for liquid ingredients to 4.3 litres. The lid also features a 5 cm wide feed tube for easy filling while the machine is running.

Adapted speeds

The VCB-61 has one speed; 1.500 rpm. It also features a direct action pulse function. This pulse function provides direct access to 1.500 rpm without any irritating time delays.

The VCB-62-3PH can run at two speeds;

- 1,500 rpm for gentle preparation and better control when chopping, and

- 3,000 rpm for rapid mixing or blending of sauces or minced meats.

User friendly ergonomics

The machine is controlled using one knob instead of several buttons required with other brands. The knob is located on the left hand side allowing your right hand to remain free for the scraper or for filling. The knob is at a convenient height to ensure an ergonomic working posture.

Only the best material

The machine base is manufactured of robust metal. The bowl is manufactured in stainless steel, whilst the lid and scrapers are strong Tritan. The knife attachment is of high-quality aluminium and the knives are stainless steel.

Developed for the best hygiene

The VCB is manufactured solely from hygiene certified material. The machine has smooth surfaces, rounded edges and has no unnecessary recesses where food might penetrate and get stuck. The machine base has a drainage hole to prevent water accumulating on the top. For rapid cleaning, all loose components are easy to remove making the machine easy to rinse. You can wash all removed components in the dishwasher.

Exemplary safety features

The VCB has three individual safety switches. You can only start the machine if the bowl, lid and safety arm have been correctly fitted. The VCB has a mechanical motor brake, which means the knife stops rotating immediately when you switch off the machine. As the motor brake is mechanical, it also works in the event of electrical faults or power failures.

Unique knife unit

The VCB knife unit is totally unique and has a patented design. Instead of the customary two knives, this vertical cutter has four. The two large knives cut the ingredients while the two small turning knives push the ingredients down into the cutting knives and turn them. This cuts preparation time considerably and ensures more even results. The cutting knives are serrated in order to maintain their sharpness longer. When you prepare food in a vertical cutter these is risk of heat due to friction from the knives. The shape of the knife helps minimize this effect.

Patented scraper

The VCB has a scraper system designed to prevent food getting stuck on the inside and the lid of the bowl, where the knives are unable to reach. The scraper arms keep the lid and the inside of the bowl clean. As the same time they move the ingredients back towards the knives.

VCB’s scraper system has 4 arms. It’s patented function means that the rotation of the ingredients in the bowl is effectively stopped and they are moved back towards the knives. This accelerates the preparation time significantly and reduces heat release in the bowl.

Perfect and even results every time

The VCB delivers the best results achievable from a vertical cutter. The reason for this is the way in which the bowl, scraper and knife unit work together.

- When the knife unit rotates, the large cutting knives cut up the ingredients while pressing them forwards and out towards the side of the bowl.

- When the ingredients reach the edge of the bowl, their rotation is stopped and the four scraper arms throw them back towards the knives.

- While the scraper keeps the ingredients away from the inside of the bowl, the hexagonal shape of the knife unit forces the

ingredients to bounce away from the middle.

- The smaller turning knives, which are unique to VCB, presses the ingredients down towards the cutting knives and turns them around ensuring the entire contents of the bowl are prepared equally and you get a more even result.

These functions allow you to shorten preparation time significantly and thereby reduce the heat release that may arise in the bowl.

Net weights

Machine VCB-62-3PH: 25 kg.

Machine VCB-61: 25 kg.

Bowl complete: 2.6 kg.

Your easy way to get 3 years warranty

Complete the warranty registration form for all purchases of Hallde Food Preparation Machines in Australia and you are entitled to a 24 month warranty extension. This extension increases the warranty of your machine to three (3) years parts & labour. (Standard warranty is one (1) year parts & labour). Terms and conditions of the warranty applicable at the time of purchase apply to this Warranty Extension. Please refer to these original warranty conditions set out in the Owners Manual supplied with your machine.

Warranty Application Process

The extension application form must be completed and returned to Hallde within 30 days of purchase. Send the form, including a copy of your purchase invoice direct to Hallde in Sweden.