| Model Number |

Description |

RRP AUD

Ex GST |

|

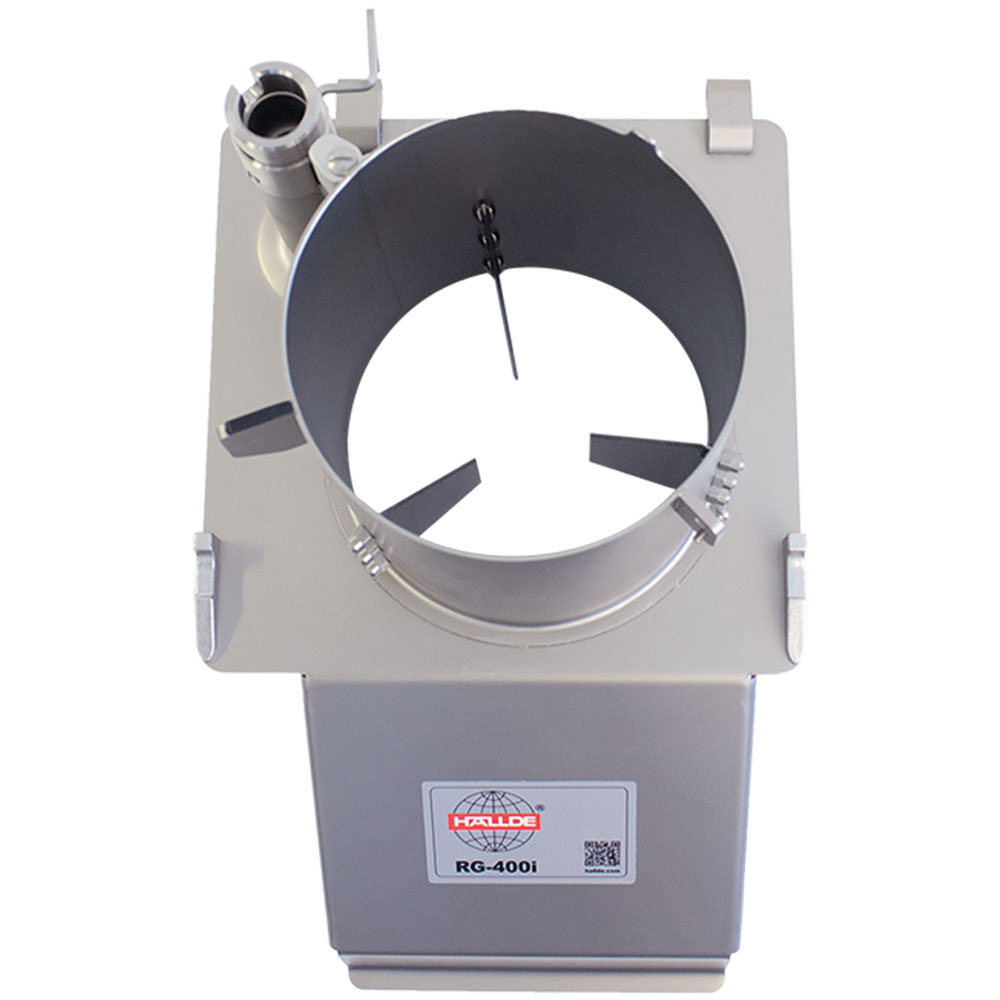

RG-400i-3PH Accessories |

|

| HA1076 |

Wall Rack for 3 Plates/Grids |

$ 60 |

| HA10037 |

Cleaning Brush |

$ 20 |

| HA10020 |

Cleaning Brush Large |

$ 53 |

| HA37297 |

Insert Tray A (supplied with new machines, for high production fast cleaning) |

$ 977 |

| HA3208 |

Accessories Trolley, Stainless Steel, with lockable wheels. |

$ 4,351 |

| HA40721 |

Container Trolley, Stainless Steel, with handle, lockable wheels, adjustable level to suit gastronorm container 1/1-200. |

$ 1,220 |

|

RG-400i-3PH Feed Attachments |

|

| HA37091 |

Continuous feed hopper (includes feed cylinder) |

$ 9,346 |

| HA37105 |

4 tube feeder |

$ 3,514 |

| HA37060 |

Manual push feeder |

$ 3,039 |

| HA37106 |

Pneumatic push feeder |

$ 10,713 |

| HA37063 |

Type A feed cylinder (includes three internal knives) |

$ 5,019 |

| HA37202 |

Type B feed cylinder (includes one internal wall) |

$ 4,872 |

|

RG-400i-3PH Cutting Tools |

|

| HA63082 |

Slicer 0.5 mm – blade replaceable |

$ 546 |

| HA63081 |

Slicer 1 mm – blade replaceable |

$ 546 |

| HA63023 |

Slicer 1.5 mm – blade replaceable |

$ 546 |

| HA63026 |

Slicer 2 mm – blade replaceable |

$ 546 |

| HA63045 |

Slicer 3 mm – blade replaceable |

$ 546 |

| HA63056 |

Slicer 4 mm – blade replaceable |

$ 546 |

| HA63083 |

Slicer 5 mm – blade replaceable |

$ 546 |

| HA63046 |

Slicer 6 mm – blade replaceable |

$ 546 |

| HA63084 |

Slicer 7 mm – blade replaceable |

$ 546 |

| HA63042 |

Slicer 8 mm – blade replaceable |

$ 546 |

| HA63085 |

Slicer 9 mm – blade replaceable |

$ 546 |

| HA63033 |

Slicer 10 mm – blade replaceable |

$ 546 |

| HA65040 |

High Capacity Slicer 2 mm – double blades, blades replaceable |

$ 1,157 |

| HA65045 |

High Capacity Slicer 3 mm – double blades, blades replaceable |

$ 1,157 |

| HA65041 |

High Capacity Slicer 4 mm – double blades, blades replaceable |

$ 1,157 |

| HA65042 |

High Capacity Slicer 6 mm – double blades, blades replaceable |

$ 1,157 |

| HA65043 |

High Capacity Slicer 8 mm – double blades, blades replaceable |

$ 1,157 |

| HA65044 |

High Capacity Slicer 10 mm – double blades, blades replaceable |

$ 1,157 |

| HA65018 |

High Capacity Slicer 12 mm – double blades, blades replaceable |

$ 1,157 |

| HA65021 |

High Capacity Slicer 15 mm – double blades, blades replaceable |

$ 1,157 |

| HA65024 |

High Capacity Slicer 20 mm – double blades, blades replaceable |

$ 1,157 |

| HA62320 |

Fine Cut Slicer 14 mm – blade replaceable |

$ 1,139 |

| HA62322 |

Fine Cut Slicer 20 mm – blade replaceable |

$ 1,139 |

| HA62573 |

Soft Slicer 8 mm – blade replaceable |

$ 589 |

| HA62575 |

Soft Slicer 10 mm – blade replaceable |

$ 589 |

| HA62577 |

Soft Slicer 12 mm – blade replaceable |

$ 589 |

| HA62579 |

Soft Slicer 15 mm – blade replaceable |

$ 589 |

| HA63343 |

Crimping Slicer 3 mm – blade replaceable |

$ 546 |

| HA63074 |

Crimping Slicer 4 mm – blade replaceable |

$ 546 |

| HA63345 |

Crimping Slicer 5 mm – blade replaceable |

$ 546 |

| HA63039 |

Crimping Slicer 6 mm – blade replaceable |

$ 546 |

| HA65060 |

High Capacity Crimping Slicer 2 mm – double blades, blades replaceable |

$ 1,162 |

| HA65063 |

High Capacity Crimping Slicer 3 mm – double blades, blades replaceable |

$ 1,162 |

| HA65061 |

High Capacity Crimping Slicer 4 mm – double blades, blades replaceable |

$ 1,162 |

| HA65062 |

High Capacity Crimping Slicer 6 mm – double blades, blades replaceable |

$ 1,162 |

| HA63212 |

Julienne Cutter 2 x 2 mm – blade replaceable |

$ 589 |

| HA63348 |

Julienne Cutter 2 x 6 mm – blade replaceable |

$ 589 |

| HA63349 |

Julienne Cutter 3 x 3 mm – blade replaceable |

$ 589 |

| HA63061 |

Julienne Cutter 4 x 4 mm – blade replaceable |

$ 589 |

| HA63065 |

Julienne Cutter 6 x 6 mm – blade replaceable |

$ 589 |

| HA63073 |

Julienne Cutter 8 x 8 mm – blade replaceable |

$ 589 |

| HA63080 |

Julienne Cutter 10 x 10 mm – blade replaceable |

$ 589 |

| HA65000 |

High Capacity Julienne Cutter 2 x 2 mm – blade replaceable |

$ 1,252 |

| HA65049 |

High Capacity Julienne Cutter 2.5 x 2.5 mm – blade replaceable |

$ 1,252 |

| HA65004 |

High Capacity Julienne Cutter 4 x 4 mm – blade replaceable |

$ 1,252 |

| HA65007 |

High Capacity Julienne Cutter 6 x 6 mm – blade replaceable |

$ 1,252 |

| HA65010 |

High Capacity Julienne Cutter 8 x 8 mm – blade replaceable |

$ 1,252 |

| HA65015 |

High Capacity Julienne Cutter 10 x 10 mm – blade replaceable |

$ 1,252 |

| HA62630 |

Grater/Shredder 1.5 mm – blade replaceable |

$ 519 |

| HA62631 |

Grater/Shredder 2 mm – blade replaceable |

$ 519 |

| HA62632 |

Grater/Shredder 3 mm – blade replaceable |

$ 519 |

| HA62633 |

Grater/Shredder 4.5 mm – blade replaceable |

$ 519 |

| HA62634 |

Grater/Shredder 6 mm – blade replaceable |

$ 519 |

| HA62635 |

Grater/Shredder 8 mm – blade replaceable |

$ 519 |

| HA62636 |

Grater/Shredder 10 mm – blade replaceable |

$ 519 |

| HA62637 |

Fine Grater – blade replaceable |

$ 546 |

| HA62639 |

Hard Cheese Grater – blade replaceable |

$ 546 |

| HA62638 |

Fine Grater, Extra Fine – blade replaceable |

$ 546 |

|

New Dicing Grids – use with appropriate slicers from above, as detailed below

Note – From mid 2019, all RG-400i machines are supplied with Insert Tray A (HA37297) making the RG-350 dicing grids below compatible with the RG-400i.

|

|

| HA37177 |

Dicing Grid 6 x 6 mm – use with 3 mm–6 mm Slicers or High Capacity Slicers |

$ 1,269 |

| HA37178 |

Dicing Grid 8 x 8 mm – use with 3 mm–8 mm Slicers, 8 mm Soft Slicer or 4-8mm High Capacity Slicers |

$ 1,269 |

| HA37179 |

Dicing Grid 10 x 10 mm – use with 3 mm–10 mm Slicers, 8 mm-10 mm Soft Slicers or 4-10mm High Capacity Slicers |

$ 1,269 |

| HA37180 |

Dicing Grid 12 x 12 mm – use with 3 mm–10 mm Slicers, 8 mm-10 mm Soft Slicers or 4-10mm High Capacity Slicers |

$ 1,269 |

| HA37181 |

Dicing Grid 12 x 12 mm Low – use with 12 mm Soft Slicer or 12mm High Capacity Slicer |

$ 1,269 |

| HA37182 |

Dicing Grid 15 x 15 mm – use with 3 mm–10 mm Slicers, 8 mm-10 mm Soft Slicers or 4-10mm High Capacity Slicers |

$ 1,269 |

| HA37183 |

Dicing Grid 15 x 15 mm Low – use with 12 mm-15 mm Soft Slicers or 14 mm Fine Cut Slicer, or 12-15mm High Capacity Slicers |

$ 1,269 |

| HA37184 |

Dicing Grid 20 x 20 mm – use with 3 mm–10 mm Slicers, 8 mm-10 mm Soft Slicers or 4-10mm High Capacity Slicers |

$ 1,269 |

| HA37185 |

Dicing Grid 20 x 20 mm Low – use with 12-15 mm Soft Slicers, 14-20mm Fine Cut Slicers or 12-20 mm High Capacity Slicers |

$ 1,269 |

| HA37186 |

Dicing Grid 25 x 25 mm – use with 3 mm-10 mm Slicers, 8 mm-10 mm Soft Slicers or 4 mm-10 mm High Capacity (HC) Slicers |

$ 1,269 |

| HA37187 |

Dicing Grid 25 x 25 mm Low – use with 12 mm-15 mm Soft Slicers, 14 mm-20 mm Fine Cut Slicer or 12 mm-20 mm High Capacity (HC) Slicers |

$ 1,269 |

|

Old Dicing Grids mid 2019 – use with appropriate slicers from above, as detailed below

Note – the old dicing grids below are compatible with RG-400i machines purchased prior to mid 2019. These grids will be discontinued once stock runs out. After this, the new dicing grids in the following section can be used in all RG-400i machines when used with Insert Tray A (HA37297), which is available separately. |

|

| HA37188 |

Dicing Grid 6 x 6 mm – use with 3 mm–6 mm Slicers or High Capacity Slicers |

$ 1,409 |

| HA37190 |

Dicing Grid 10 x 10 mm – Use with 3 mm–10 mm Slicer, 8 mm-10 mm Soft Slicer or 4 mm-10 mm High Capacity (HC) Slicers |

$ 1,409 |

| HA37191 |

Dicing Grid 12 x 12 mm – use with 3 mm–10 mm Slicers, 8 mm-10 mm Soft Slicers or 4-10mm High Capacity (HC) Slicers |

$ 1,409 |

| HA37195 |

Dicing Grid 12 x 12 mm Low – use with 12 mm Soft Slicer or 12mm High Capacity (HC) Slicers |

$ 1,409 |

| HA37196 |

Dicing Grid 15 x 15 mm Low – use with 12 mm-15 mm Soft Slicers or 14 mm Fine Cut Slicer, or 12-15mm High Capacity (HC) Slicers |

$ 1,409 |

| HA37193 |

Dicing Grid 20 x 20 mm – use with 3 mm–10 mm Slicers, 8 mm-10 mm Soft Slicers or 4-10mm High Capacity (HC) Slicers |

$ 1,409 |

| HA37197 |

Dicing Grid 20 x 20 mm Low – use with 12-15 mm Soft Slicers, 14-20mm Fine Cut Slicers or 12-20 mm High Capacity (HC) Slicers |

$ 1,409 |

| HA37194 |

Dicing Grid 25 x 25 mm – use with 3 mm-10 mm Slicers, 8 mm-10 mm Soft Slicers or 4 mm-10 mm High Capacity (HC) Slicers |

$ 1,409 |

| HA37198 |

Dicing Grid 25 x 25 mm Low – use with 12 mm-15 mm Soft Slicers, 14 mm-20 mm Fine Cut Slicer or 12 mm-20 mm High Capacity (HC) Slicers |

$ 1,409 |

|

Potato Chip Grid

Note – An Insert Tray A (HA37297) is required to use the Potato Chip Grid in RG-400i machines. RG-400i machines purchased after mid 2019 include this tray, for older machines, the tray can be purchased separately. |

|

| HA37176 |

Potato Chip Grid – use only with 10 mm Slicer, 10 mm Soft Slicer or 10 mm High Capacity (HC) Slicer |

$ 1,269 |

|

Recommended Cutting Tools with first purchase – RG-400i-3PH |

|

| Kit 7* |

2 Wall racks (HA1076), Slicer 1.5 mm (HA63023), Slicer 4 mm (HA63056), Slicer 6 mm (HA63046), Slicer 10 mm (HA63033), Grater/Shredder 4.5 mm (HA62633), Dicing Grid 10×10 mm (HA37179) |

|

| Kit 8* |

3 Wall racks (HA1076), Slicer 1.5 mm (HA63023), Slicer 4 mm (HA63056), Slicer 6 mm (HA63046), Slicer 10 mm (HA63033), Julienne Cutter 4×4 mm (HA63061), Grater/Shredder 2 mm (HA62631), Grater/Shredder 8 mm (HA62635), Fine Grater (HA62637), Dicing Grid 10×10 mm (HA37179) |

|

|

*Individual items sold separately |

|